Advantages of the HEICO-TEC® Tension Nut

SIMPLE

A hand-held torque wrench is all you need for tightening and loosening. No special tools are required. This makes maintenance far easier.

FAST

Manual pretensioning saves on the transport and set-up times that would be required by special tools. HEICO-TEC® Tension Nuts are often tightened in the same time it takes to set up electric, hydraulic or pneumatic tools.

RELIABLE

The pressure pins act like springs and increase the flexibility of the bolted joint. This compensates for settlement of the joint, thus preserving preload.

SAFE

With the inherent mechanical elasticity of the HEICO-TEC® design, the bolted joint performs as if it has a greater clamping length, making it highly resistant to loosening forces.

DURABLE

The greater flexibility reduces the bolted joint’s dynamic stress, thus increasing its service life.

PRECISE

Controlled friction characteristics ensure the highest tightening and repeat accuracy – guaranteed and confirmed by DNV GL.

REUSABLE

As the HEICO-TEC® assembly is not damaged during tightening and loosening, the HEICO-TEC® Tension Nuts are reusable.

COMPATIBLE

HEICO-TEC® Tension Nuts comply with all ISO 898-2 requirements. You can directly replace any conventional nut from the same strength class.

ECONOMICAL

Our efficient and high volume manufacturing process means that we can transfer the cost benefits directly to our customers

The better Alternative

Compared with conventional methods, HEICO-TEC® Tension Nuts offer considerable advantages for tensioning large bolted joints quickly, simply and reliably.

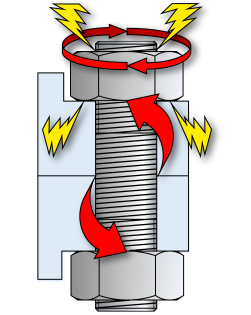

PHYSICS OF BOLT TENSIONING PROCESS

Due to the inclined plane of the bolt threads, the turning movement of bolt tightening results in axial elongation and preload of the bolt.

PROBLEMS:

- Threads are deformed even when proper lubrication is applied.

- The deformation of the threads reduces the preload, durability, and reusability of the bolt.

- The torsion stress from thread friction and deformation reduces the axial load-bearing capacity of the bolt.

ADVANTAGES OF HEICO-TEC®

No torsion stress. As the stress on the bolt is purely axial, the capacity of the bolt can be fully utilized.

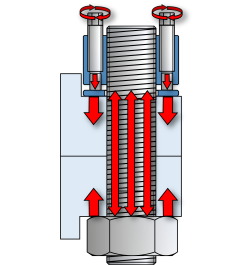

THE HYDRAULIC TENSIONING PROCESS

When tightening a bolt with a hydraulic cylinder, the bolt is elongated and the nut is then tightened free of load. When the hydraulic pressure is released, the bolt contracts, resulting in the proper tension on the bolt.

PROBLEM:

As the nut was not pretensioned while the bolt was elongated, a percentage of the elongation of the bolt is lost in joint settlement. Only two thirds of the bolt strength can be utilized.

ADVANTAGES OF HEICO-TEC®

Losses from settlement of the joint do not occur and full capacity of the joint is achieved.

TENSION NUTS WITH PRESSURE BOLTS PROCESS

In the case of tension nuts with pressure bolts, the pressure bolts are arranged closer to the bolt thread and have a smaller hexagon head.

PROBLEMES:

- With less space to maneuver, this tensioning system results in higher costs due to the need for a special thin-walled socket and wrench.

- Typically, this tension system is not as strong as standard hex nuts. In this case, standard tension nuts with pressure bolts cannot replace commercial hex nuts.

ADVANTAGES OF HEICO-TEC®

Nuts can be installed with standard industrial-quality wrenches